GENERAL

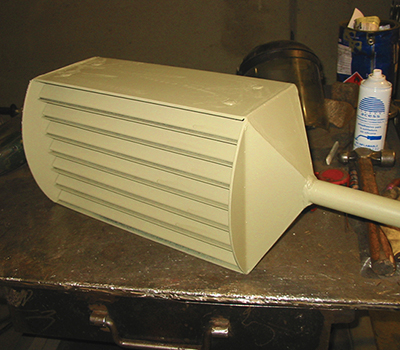

Vane filters are especially designed to separate out liquid particles in gas flows.

These types of filters are generally used to protect regulation and measurement stations, valve stations, gas transfer stations, etc.

They are particularly useful for operations in which liquid or humidity is transported by the gas, thus potentially damaging the installation.

They are used, for example, in turbines or air/gas compression units, chemical industry processes, in the food industry, etc.

HOW THEY WORK

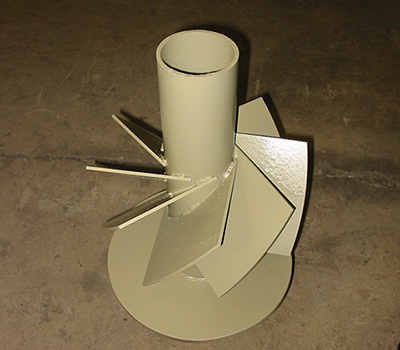

Vane filters include a series of parallel components (walls) which form irregular paths (non-linear) as well as other components that continuously force the flow of gas to change direction, provoking turbulence as the gas is pushed against the walls, wetting these. As a result, droplets are formed and enlarged which, by the weight of gravity, slowly slide down the walls.

The liquid gathered by this series of filters is driven directly to the bottom of the tank, removed from the primary gas flow.

PRESSURE DROP

As they are fixed in position, filter efficiency varies depending on the gas flow (faster or slower) and the size and distribution of the liquid particles.

EFFICIENCY

8μ > up to 98%