GENERAL

The odorization of the natural gas network system is necessary for an efficient identification of leaks and guarantee the safe of the people and installations.

The addition of odorant must be the necessary that the human smell sensibility was capable to detect a leakage.

To obtain it, is necessary to add few quantities of THT, TBM, DMS, etc inside the gas flow.

All those liquids contain a few position of sulphur.

TECHNICAL INFORMATION

Electronic and pneumatic systems.

Explosion proof security (Eex d).

Compact systems of reduced volume.

Is not necessary a special installation.

Completely automatic systems, easy to use.

SATURATION ODORIZING SYSTEMS

DESCRIPTION

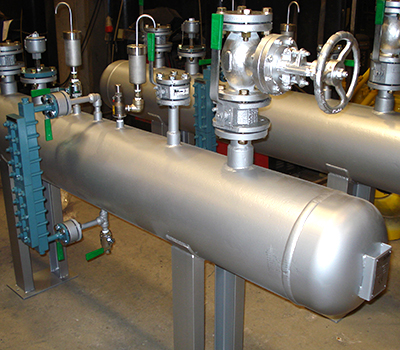

The system is basically integrated by a cylindrical reservoir and a diaphragm

put into the gas flow.

The reservoir is linked to diaphragm input and output. Can be filled until 75% of its total capacity.

Working principle is based mainly in differential pressure produced by the diaphragm.

Regulation is adjusted by a needle valve introduced in the link of the reservoir.

AUTOMATIC INJECTION SYSTEMS

GENERAL

Automatic systems are powered by pumps, thouse are metering pumps through which the odorizer liquid is injected proportionally into the gas flow.

The system manapeg by electronic devices guarantees proportional quantity of odorant inside the gas flow according its metering system.

TECHNICAL INFORMATION

- Odorizing: All types.

- Materials: stainless Steels AISI304.

- Working pressure: Up to 20 bar.

- Working temperature: Up to 60°C.

- Auxiliar vessel: 5 liters.

- Dosification: Programmable.