GENERAL

Heat exchangers make the function of preheating gas before regulating it to balance the cooling due to decompression.

With this we can avoid internal balances (if gas drags liquid particles) and external balances of environment air humidity and consequently, obstruction problems of ice-formation in mechanical elements or pressure regulated pneumatic elements are also avoided. Moreover, corrosion in piping and the regulation station or plant and measure or treatment of gas fluid is minimized.

These exchangers are usually mounted vertically.

The standard heating fluids are heated water or water vapour.

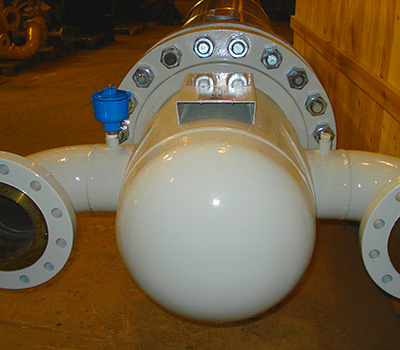

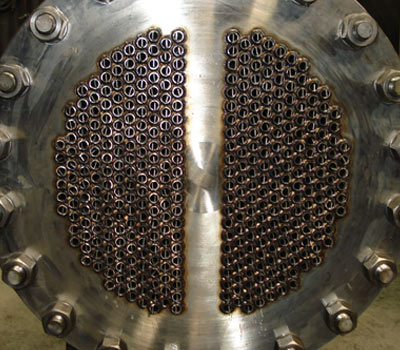

The most common kind of exchanger is the so-called “shell-and-tube”, which satisfies the most favourable relation of covered heating surface in the shell area by heating fluid, coming from a generation centre or surplus of the plant or factory if it is the case.

WHY DOES IT HAPPEN?

When natural gas is submitted to reduction of pressure, temperature falls.

This is due to the physic law known as the “Joule-Thomson” effect, which according to the gas, its temperature and the pressure differential determines the temperature fall. For an average natural gas at a maximum pressure of 100 bar, this temperature fall is usually around 0.4˚C per bar of reduction of pressure.

VESSEL MATERIALS

The most commonly used materials are non-alloy steel and stainless steel.

It is important to highlight that stainless steel has lower a thermal conductivity coefficient than carbon steel. Due that are needed bigger transfer surfaces and bigger, too, vessel size.

GENERAL CHARACTERISTICS

Construction

- Design code:

- EN 13445.2000

- ASME VIII div. 1

- A D Merkblatt 2000

- Design pressure:

- +153 [Bar]

- (2.220 psi)

- Certification: CE 97/23 or ASME U stap

OTHER KINDS

The heating system might be presented in different configurations.

MIX EXCHANGERS

Vertical assembling, used in fuel gal boiler power supply stations to avoid condensing when starting up.

ELECTRICAL EXCHANGERS

Certain kind of installations that require few control or maintenance can be installed electrical exchangers.

This kind of exchangers is horizontally built to make the thermo siphon principale action easier.