GENERAL

Used to vaporize liquid gases (Propane, Butane, etc).

This operation can be done into the GPL vessel, but where its vaporizing capacity is not enough, it is necessary to do this operation in an auxiliary place which can guarantee gas necessary flow, and gas quality to be constant avoiding distillation of different components.

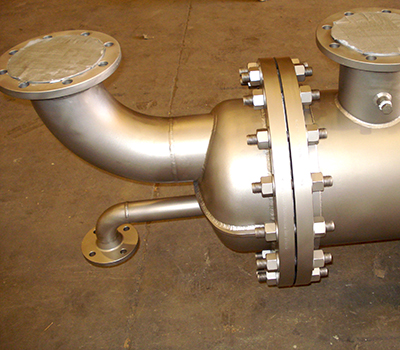

This process can be attained by a heat change, using as heating fluid a mix of water and glycol.

The heat is delivered through the tubular part to the liquid gas allowing it to change its state.

Necessary energy to vaporize 1 Kg of liquid propane is 101.6Kcal.

It is not recommendable to adjust too much the production capacity of this element. It is recommended at the same time to have a heating water temperature between 50˚C and 60˚C, obtaining by this an average gas quality allowing thus to decrease condensed depositions.

In the outlet part of the vaporizer, must be installed before the regulation lines, a collector to receive oils and condensed parts that could be brought by the gas.

All vaporizers have a system to avoid the pass of liquid to the rest of the installation.

Also a safety valve of 20 bar is mandatory.

Teyco’s vaporizers are CE certified under Directive 97/23 CE B+D module.

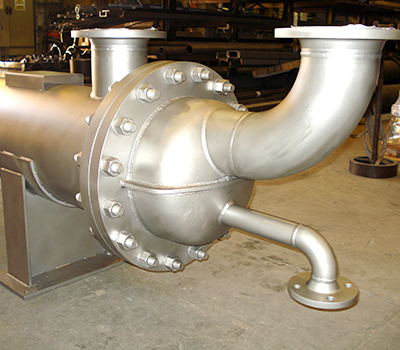

FEEDBACK SYSTEM

- Takes advantage of both:

Direct vaporization to reservoir.

Heat absorption vaporization. - It acts when pressure drop happens into outlet side.

- It works continuously in liquid state, with a high degree in thermical transfer efficiency.

- Construction materials used the same than in fee-out system.