FILTER SEPARATOR

Filters separators are used when guaranteeing efficiency in the filtration level that conventional filters do not ensure is necessary. They are highly fficient separators.

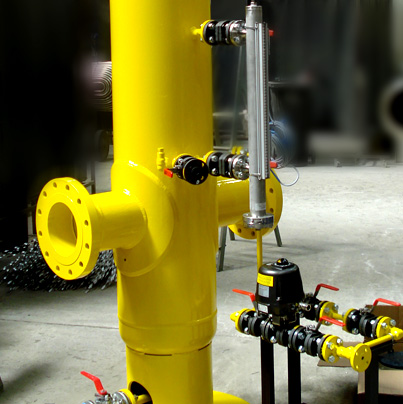

These filters can be horizontally or vertically built.

This kind of filters is specially applied to transmission systems with regulators, compressors and to generation centrals where turbines are used.

Filtration level depends, like coalescent filters, on the kind of cartridge used, the flow direction and the recipient’s configuration.

WORKING PRINCIPLE

Efficacy is reached with a double filtering stage.

The first one is for separating liquid and solid particles, or only liquid, and the second one is made through a vane unit for liquid particles.

Basically, the difference between these filters being horizontal or vertical is that in horizontal configuration the biggest solid or liquid particles when entering the recipient and

crashing against the mechanical elements and directly plunged before entering the coalescent filtering cartridge.

Accumulated liquid descends to an auxiliary recipient placed in the lower part, avoiding to be mixed up newly with the gas flow.

It is important to consider too that in horizontal configuration, difficult connection figures between inlet and outlet of the filter to the process are avoided.

Pressure drop of this kind of filters is not high, although gas flow passes through a

double filtering process.

EFFICIENCY

In general, the following percentages of separation can be considered:

100% of liquid particles from 5 to 10μ.

99.5% of liquid particles from 1 to 3μ.

100% of solid particles from 1 to 3μ.

99% of solid particles of 0.5μ.

PRESSURE DROP

The design of this kind of filters works with pressure drops between 0.1 to 1.