GENERAL

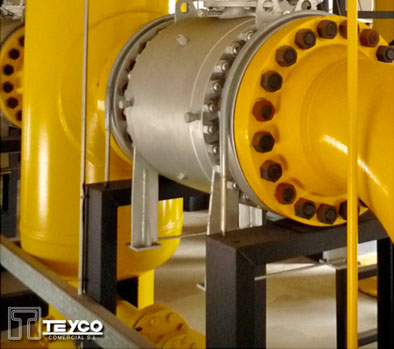

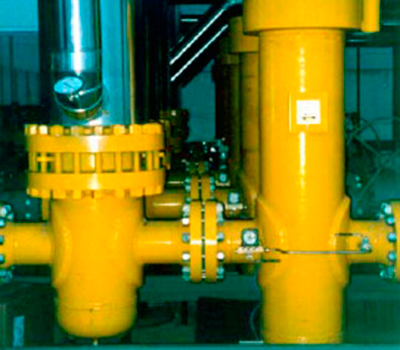

Cartridge filters are designed to separate out impurities, rust from pipes, etc.

These types of filters are used especially to protect regulation and measurement stations, RMS, valve stations, gas transfer stations, etc.

Replaceable cartridges thus protect regulators, meters, valves, turbines, compressors and other in line mounted equipment.

HOW THEY WORK

Gas enters the recipient and is slowed down, thereby using gravity to deposit the largest particles on the bottom.

The cartridges guarantee that solid impurities within the gas flow are separated out.

There are different cartridges offering varying degrees of filtering capabilities depending on service client’s needs.

The pressure drop resulting from these types of filters is relatively low.

CARTRIDGES

SUPPORT

- Simple steel mesh or reinforced with

- perforated plate supports.

- Crush resistance: 1 to 3 bar.

FILTERING MATERIAL

Textile, polyester or paper fibres.

EFFICIENCY (textile fibres)

- 5μ CARTRIDGES

- 98% > 3μ

- 99% > 5μ

- 1μ CARTRIDGES:

- 98% > 1μ

- 99.5% > 2μ

PRESSURE DROP

The design of these filters normally allows for a pressure drop ranging from 0.05 to 0.5 bar approximately.